Global Trend: Why Aluminum Profiles Dominate High-End Manufacturing?

Views : 15

Update time : 2025-12-16 17:32:49

In 2025, the global high-end aluminum profile market is set to exceed $100 billion, with China accounting for over 62% of global production capacity. This growth isn’t accidental—aluminum profiles have become irreplaceable in key industries due to their unique combination of lightweight strength, corrosion resistance, and 100% recyclability. From new energy vehicles to solar power systems, from architectural curtain walls to 5G infrastructure, their versatility drives innovation across sectors.

Core Applications: Where Aluminum Profiles Create Value

1. New Energy & Transportation

- EV Battery Packs: Aluminum profiles reduce vehicle weight by 30% while enhancing structural safety, with per-car usage expected to reach 260kg by 2030.

- Solar Supports: Replacing traditional steel, aluminum profiles withstand extreme weather and extend system lifespan by 15+ years.

- Rail Transit: High-strength aluminum ensures stability for high-speed trains and subways, with annual demand growing at 8%.

2. Architecture & Construction

- Green Buildings: Energy-saving aluminum curtain walls reduce carbon emissions by 40% compared to traditional materials, meeting global green building standards (LEED, BREEAM).

- Commercial Spaces: Customizable LED aluminum profiles (for malls, hotels, offices) blend aesthetics with functionality, a top choice for architects worldwide.

3. High-End Manufacturing

- 5G Infrastructure: Precision aluminum components ensure signal stability for base stations, supporting 5G network expansion.

- Industrial Equipment: Corrosion-resistant profiles adapt to harsh working environments (chemical plants, marine facilities), reducing maintenance costs by 50%.

Our Competitive Advantages: Beyond Standard Products

As a leading aluminum profile manufacturer with 20+ years of experience, we offer tailored solutions for global partners:

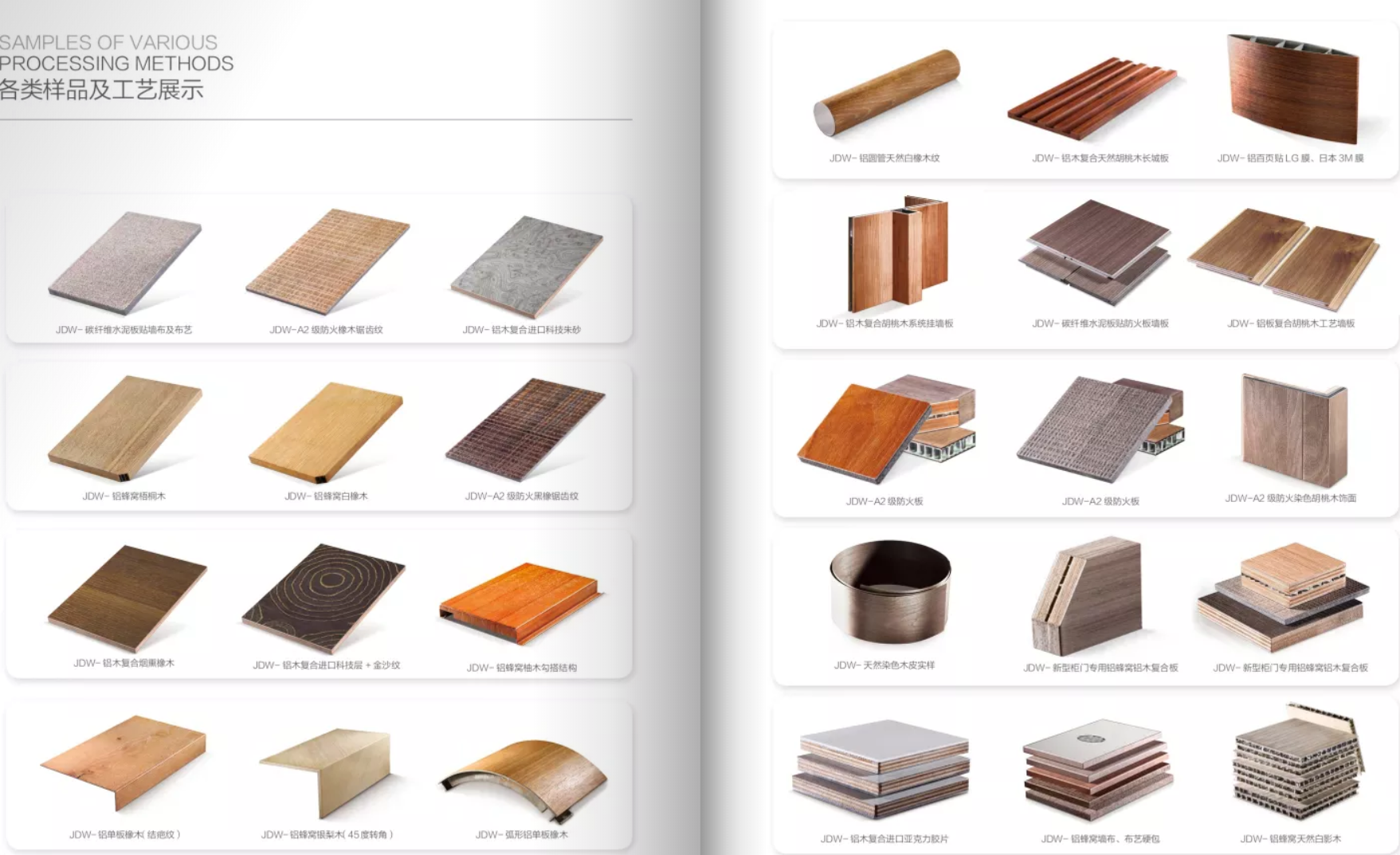

- Customization Capabilities: Full OEM/ODM services for special sizes (0.8mm-20mm thickness), surface treatments (anodizing, powder coating, wood grain transfer), and performance requirements (high strength, thermal insulation).

- Green Production: 42% of raw materials use recycled aluminum, achieving carbon neutrality in production and meeting EU environmental footprint certification (EPD).

- Global Compliance: Certified with ISO9001, CE, ROHS, and ASTM standards, fully compliant with European, North American, and Southeast Asian industry regulations.

- Efficient Supply Chain: 7-day delivery from overseas warehouses (Dubai, Germany, Mexico) and 24/7 technical support via email/Zoom.

Let’s Collaborate on Your Next Project

Whether you’re an architect, engineering contractor, automotive supplier, or solar energy integrator, we’re ready to support your goals:

- Provide free technical consultations and sample testing (samples delivered within 3 working days).

- Develop customized solutions based on your project drawings and performance specifications.

- Support large-scale orders with stable production capacity (100,000 tons/year) and flexible payment terms (L/C, T/T).

Take Action Now:

- Send us a DM with your project details (industry, required specifications, order quantity, delivery location).

- Email: [your-email@company.com] for a detailed quotation and technical datasheet.

- Visit our LinkedIn Page to view factory videos, client testimonials, and completed projects (link in bio).

We’ve helped 500+ global clients (including Fortune 500 companies) achieve 20-30% cost savings and 40% efficiency improvements—your success story could be next!

相关新闻